Thomson Optimum Growth® Special Flasks were designed with the unique needs of small-to-medium-scale bioprocessing applications

Sampling Flasks

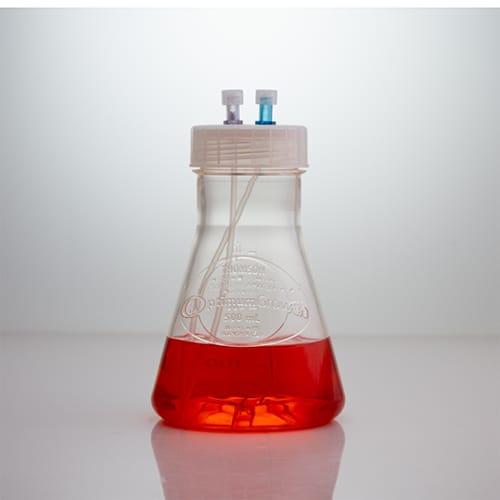

Optimum Growth® Sample Flasks with one-way sampling valves that help reduce viable cell count sampling times

Eliminate the need to remove flask caps & allow aseptic sampling on the benchtop

Multiport Flasks

Optimum Growth® Multiport Flasks serve as closed systems with feed/transfer ports

Feature feed/transfer ports for seeding larger bioreactors or for batch feeding medium sized cultures

Both aseptic sampling valves & feed/transfer ports making the 1.6L and 5L flasks closed systems

Several Options for aseptic Sampling

Optimum Growth® Flasks provide several options for aseptic sampling in all flask sizes. The 125mL, 250mL, and 500mLOptimum Growth® Flasks have an optional 1-way valve in the vented sample cap. The 5L Optimum Growth® Flask has an optional 1-way valve in the side of the flask.

The aseptic sampling option is available for the 125mL, 250mL, 500mL & 5L Optimum Growth® Flasks.

Vented Sampling Caps

The Vent Cap of the Optimum Growth® Sampling Flask incorporates a 1-way valve that only allows media to flow out of the flask. This eliminates contamination and allows for aseptic sampling of cells while the flasks remain in the shaker or on the benchtop, eliminating the need for transfer to the hood from the shaker.

Optimum Growth® Sampling Flasks come with a 0.2μm PTFE vented cap for optimum aeration during cultivation. The Thomson vented caps create a safe aseptic barrier from harmful contaminants, while the large surface area creates an optimum air exchange for cell growth.

Sampling in the Shaker

Thomson's improved sampling method allows you to sample directly in the shaker without the need to remove caps or use a deteriorating needle septum.

- Open shaker

- Attach syringe to sampling port and withdraw the sample

- Remove syringe & close shaker

Transfer & Feed Flasks

Born As A Custom Product...

The Multiport Optimum Growth® Flask was born out of the need for biopharmaceutical companies to ensure the elimination of contamination risk. The multiport flasks allows for completely closed system aseptic processing.

Steps Include:

- Addition of media to the flask

- Inoculation

- Feeding

- Sampling

125mL

250mL

500mL

1.6L

2.8L

5L

Sample Port Side

Allows viable cell count sampling while the flask remains in shaker or on benchtop

No need to decontaminate and open the flask cap

Ensures contamination-free processing

Feed Side

Tube fusing for media addition, inoculation, feeding

Transfer to larger vessel maintaining sterility

Eliminates the need to inoculate using expensive and awkward cell bags

Contamination-free processing by never needing to open the flask cap

Use the chart below to find the appropriate flask clamp compatible with your shaker.